GEAR GULP

Gear Gulp is a portable and lightweight acrylic cupholder which allows users to take their beverage on the go, and seamlessly switch between resting on a bike handle to being handheld.

SKILLS USED:

rapid prototyping, laser cutting, acrylic bending

TIMELINE :

1 week, February 2024

COURSE:

24-672: DIY Design and Fabrication

PROMPT + CONSTRAINTS:

The cupholder must fit the aesthetics of the chosen imaginary brand assigned, which was “Moody Judy Inc.” in this scenario. According to the “Moody Judy Inc” brand guidelines, the prototyped cupholder must use the least amount of the given acrylic sheet (10”x24” and 1/8” thick) as possible, and must not require any assembly.

FINAL DESIGN

IDEATION

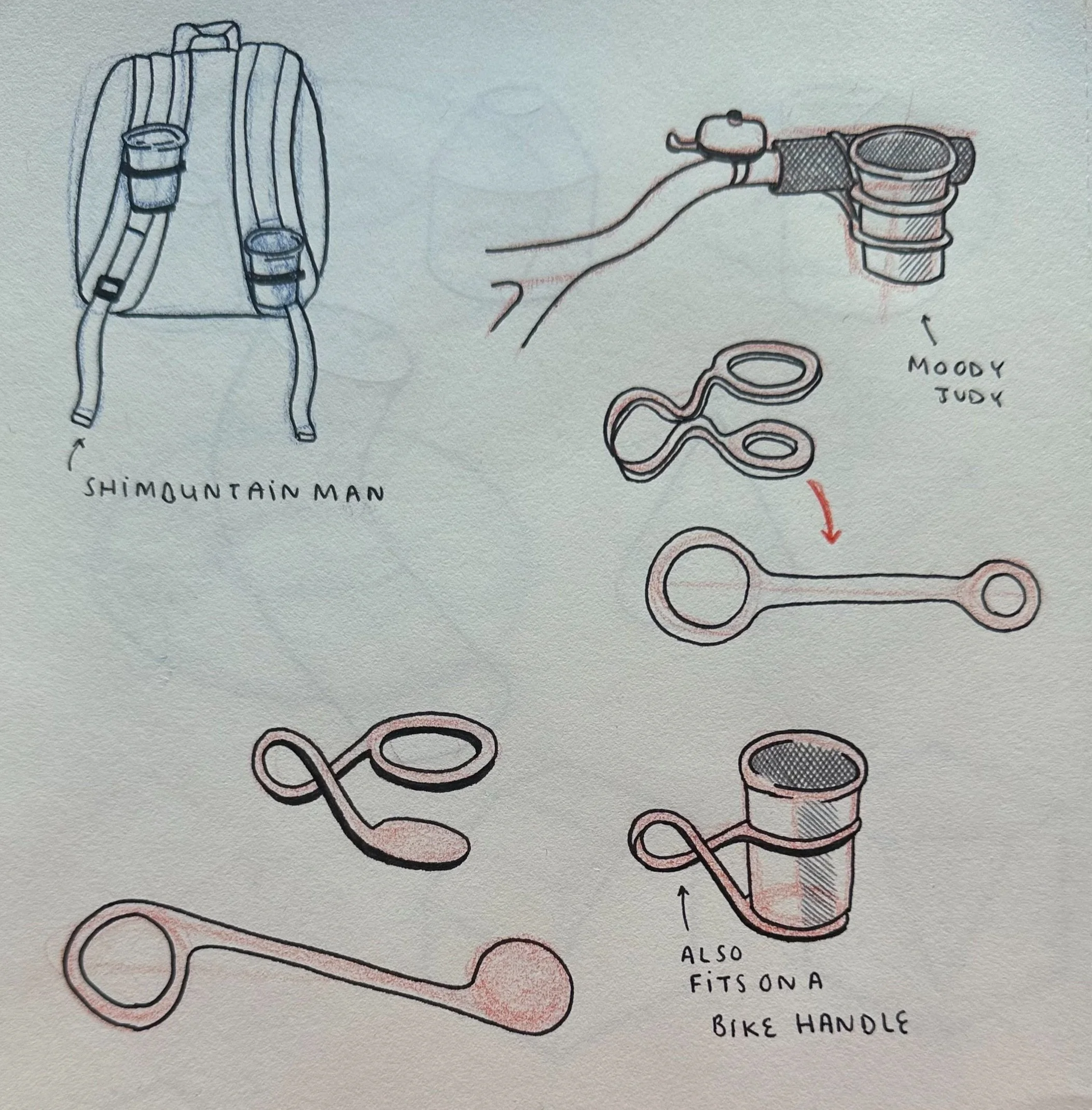

From the start, I knew that I wanted my cupholder to not only have a sleek design, but also to have a practical function/use. I began my design process by drawing concept sketches of possible dual-use designs. Next, I prototyped a few of my favorite sketches using paper to get a physical understanding of what the designs would look like once made out of acrylic.

I decided that the cupholder I would make would have a second practical use, and would be designed to rest on a bike handle, so that the user could take their drink with them on the go.

PROJECT TAKEAWAYS

Concept sketches of various designs aligning with the different listed imaginary companies talked about in class.

While I was already very familiar with prototyping using laser cutting, acrylic, and acrylic bending, this project reminded me of the importance of the conceptual design stage of projects. Had I invested more time prototyping using paper cutouts, I would have thought to create a shorter handle for the cupholder, and been happier with the overall outcome. I still enjoyed this project a lot since it moved at a faster pace, and was a good balance of being an open-ended design project while also having motivating constraints.

FABRICATION

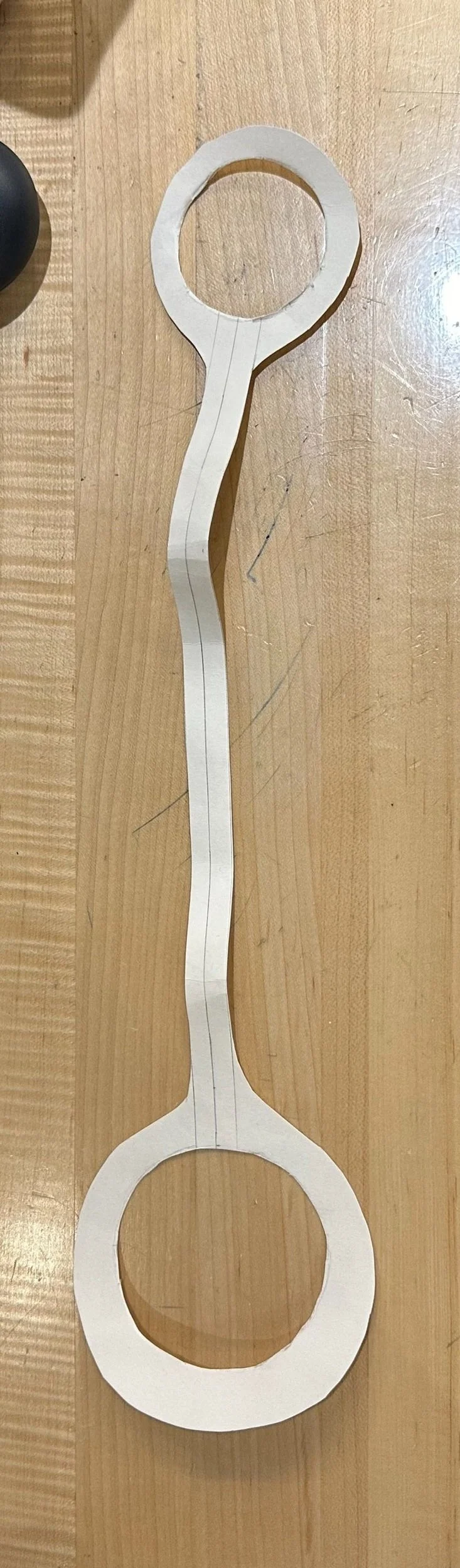

Prototyping out of paper cutouts

I liked how the paper prototype shown above looked, and made a quick .dxf file on SolidWorks for the flat pattern of it. I used the laser cutter to quickly cut out the shape in the acrylic. I then used a heat gun and various clamps which formed a rig to heat the acrylic and bend it evenly. At this point, I began to realize that the acrylic was longer than I would have liked, even though it matched the exact measurements of the paper prototype. Since the goal of the “Moody Judy, Inc” brand was to use the least amount of material as possible, I decided to continue with the bending anyways.

The final design is shown below. The image on the left shows the cupholder being actively held and in use, and the images in the middle and right shows the cupholder resting upright on the bike handle.